Scanner Controller Expandable

ScannerControlBox (SCB)

The flexible scanner control system for remote laser welding

- Compatible with all Blackbird scanners and functions

- Flexibly expandable through interface and function upgrades

- Integrated safety for maximum process reliability

- High energy efficiency with minimal operating costs

- Quick installation and maintenance-friendly architecture

The SCB Gen25 is the heart of the Blackbird system for remote laser welding and forms the central hardware platform for running the RSU user software in industrial production environments. As a logical further development of previous controller generations, it combines increased system performance, optimized energy efficiency, and a future-proof expansion concept in a compact controller design.

A key focus is on increasing efficiency and reducing operating costs: thanks to modernized hardware components and a more powerful processor design, the SCB Gen25 enables shorter cycle times (e.g., when using OCT) and lower energy consumption. At the same time, the maintenance-friendly system design reduces downtime. For customers, this means a noticeable reduction in total cost of ownership (TCO) – and a faster return on investment.

Unlike many conventional controllers, the SCB Gen25 comes with extensive integrated safety functions as standard, which reliably protect the system against operating errors, failures, or external influences.

The SCB Gen25 is also prepared for the seamless integration of additional function modules. Up to three upgrade kits can be integrated via a standardized connector base plate, whose interfaces can be used to connect sensor modules or process-accompanying monitoring functions. All extensions fit seamlessly into the existing system environment – both mechanically and in terms of software.

With its modular architecture, full backward compatibility with previous generations, and clear focus on future requirements in laser processing, the SCB Gen25 is a powerful and scalable control solution for modern manufacturing environments.

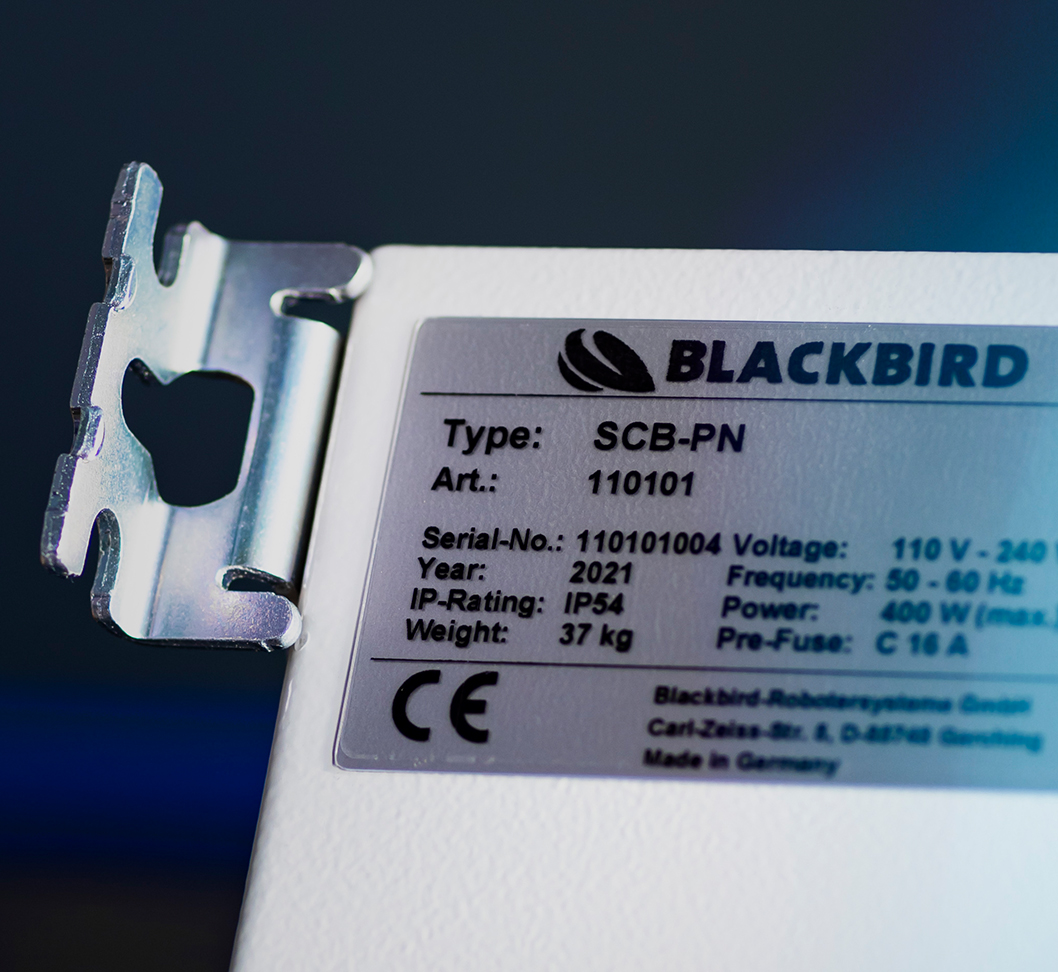

Technical Data

| Weight | 35 kg |

|---|---|

| Height | 600 mm |

| Width | 600 mm |

| Depth | 250 mm |

| Power supply | 110 – 240 VAC, 14 A |

| Integrated scanner power supply | 30 VDC |

| Fieldbus | Profinet, Ethernet/IP, DeviceNet |

| Safety interface | PROFIsafe, Hardwired |

Expansion with upgrade kits and additional function modules

Several Upgrade Kits and Function Modules are currently available for the SCB Gen25, enabling targeted expansion of the controller with additional process functionality.

The upgrade kits each contain internal components for expanding the controller and a specific interface plate that is inserted into the controller's connector base plate at the factory or in the field instead of a blanking plate. This allows additional hardware signals or modules to be flexibly integrated.

Available Upgrade Kits include:

- Upgrade Kit: OTF MotionSync

- Upgrade Kit: ScaVis

For a planned upgrade of an SCB in the field, the Pre-Installation Checklist (PDF) must be filled out in advance. This document ensures that all requirements are met. The completed file must be sent to our sales or service departments before a quotation can be created.

SCB Upgrades: Blackbird Robotersysteme GmbH

Available function modules:

- Function Module: ScaVis incl. IlluminationBox and Process Lighting

All modules can be fully integrated into the existing system environment—both mechanically and in terms of software—and are configured and managed via the central RSU user interface.

New modules are already in development and will be added shortly.

The SCB at a glance

ScannerControllBox data sheet