OCT Edge Tracking

Intelligent Edge Tracking for maximum precision in remote laser welding

OCT Edge Tracking is the powerful solution for high-precision laser welding in demanding production environments. The system detects the actual position of the component edge immediately before the welding process (pre-process) and enables dynamic adjustment of the machining path – without any loss of cycle time.

Whether complex geometries, tolerance deviations, or changing joining situations: With OCT, you can ensure reproducible welding results with maximum process stability.

Your advantages

- Precise edge tracking before welding

- Compensation for component and position deviations

- Flexible use with a wide variety of joint geometries

- Process-neutral measurement – without cycle time loss

- Real-time response to gaps and disturbances

How OCT Edge Tracking Works

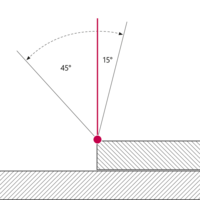

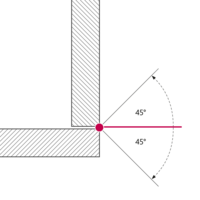

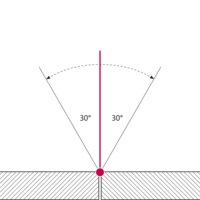

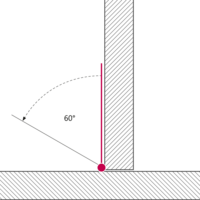

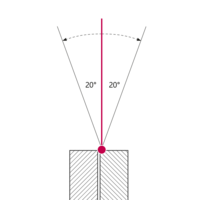

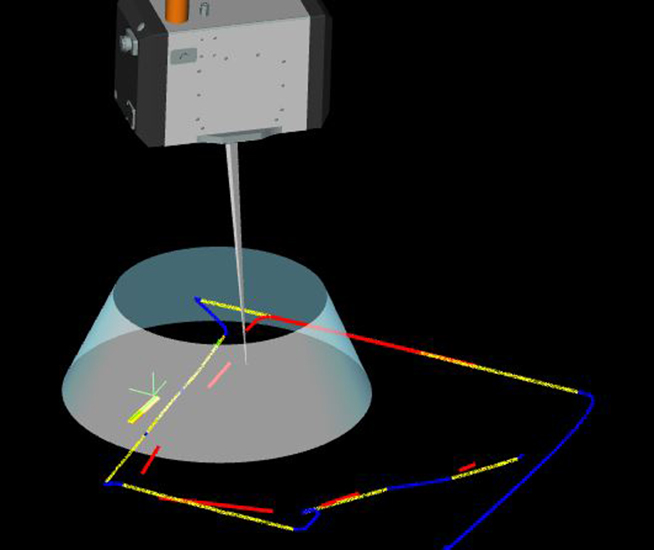

In remote laser welding, the accuracy of robot-guided movements is often insufficient to meet the high demands of modern welding processes. OCT edge tracking measures the exact position of the component edge immediately before the process – optically, contactlessly, and without delay. The system detects deviations caused by distortion, tolerances, or misalignment and adjusts the processing path in real time. Interfering geometries such as clamping devices are also detected and excluded. If several edges are in the field of view, the defined reference edge is automatically selected. The system calculates the gap between the upper and lower sheets and can automatically adjust process parameters such as laser power, beam position, and oscillation amplitude – for stable connections despite difficult joining conditions.

This allows the system to respond to a wide variety of boundary conditions and perform welding safely and with high quality.

Typical Areas of Application

OCT Edge Tracking is, among others, ideal for laser welding processes in the following areas:

- Automotive industry: bodywork, doors, seat rails, cross members

- Battery technology: cell connectors, housings, cooling plates

- Commercial vehicles / construction and agricultural machinery: structural components, frame connections

- Mechanical engineering and metalworking: precision welding on sheet metal parts

Even complex 3D scan fields with varying height levels are supported without any problems – in static operation or on-the-fly, with a fixed scanner or robot guidance.

Experience OCT Edge Tracking in Action

The video shows OCT-based Edge Tracking in practice: from precise edge detection before the welding process to dynamic adjustment of the machining path in real time.

Watch the video now and see how reliable OCT Edge Tracking makes your welding processes more stable, flexible, and efficient.