Protection of the Object During Welding

Air Management

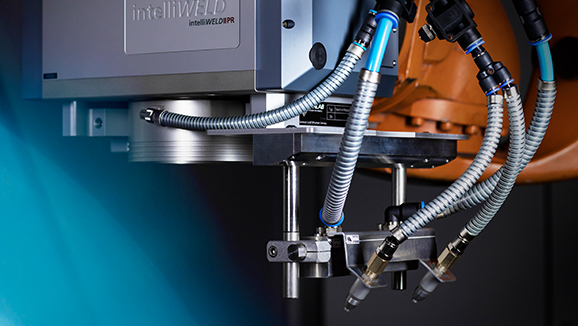

Proper air management is one of the foundations required to facilitate the successful and economic oparation of a scan system. The central tasks of the air management include the protection of the scan system and its wear parts against contamination and to keep the process area free of smoke residue to permit an unhindered coupling of the laser beam. After more than a decade of practical experience in the area of laser welding, Blackbird offers a comprehensive and proven package that guarantees a maximum service life of its system even in demanding environments.

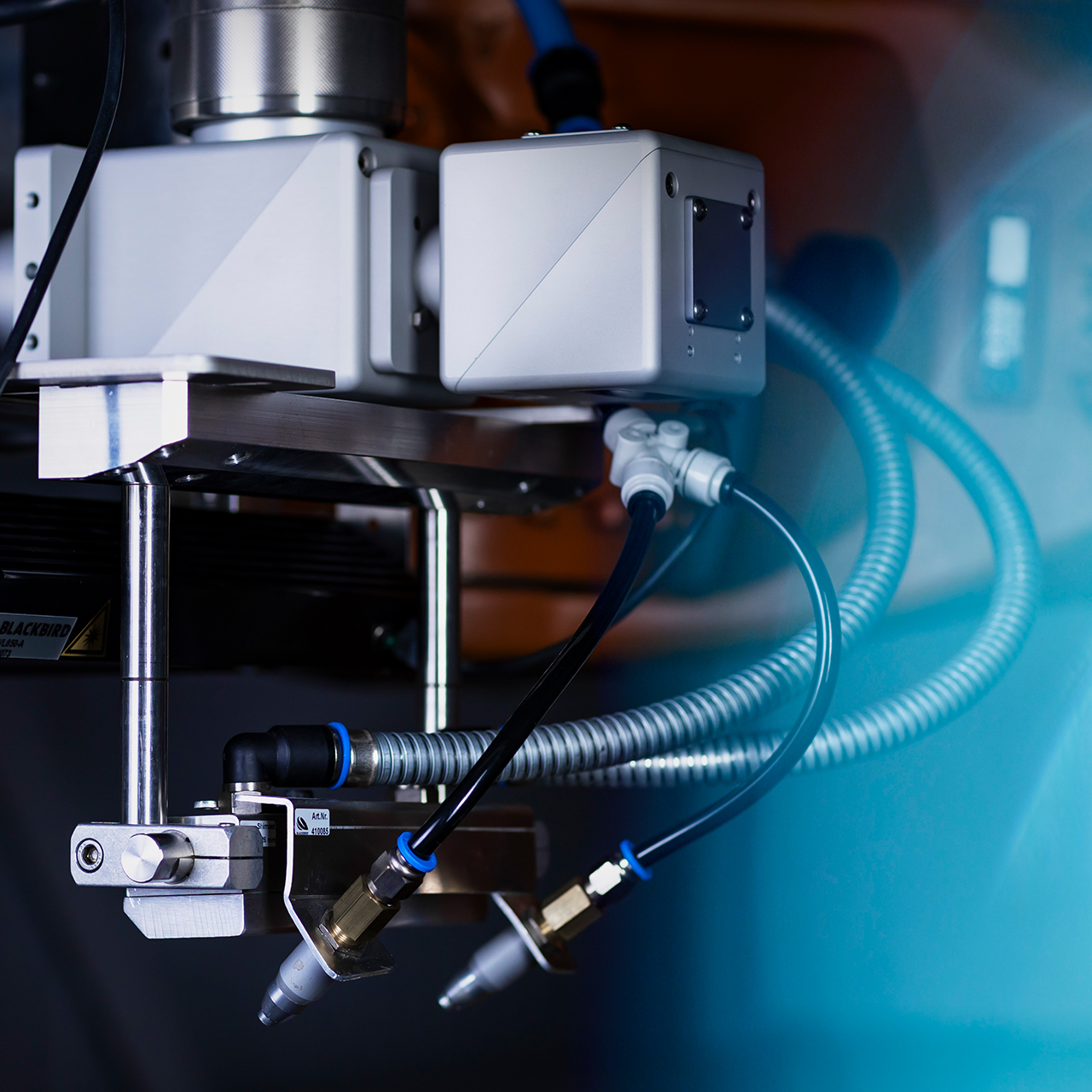

The main parts of the air management are Crossjet, process nozzles, a Fume Protection Module and a Purge Air Filter Combination.

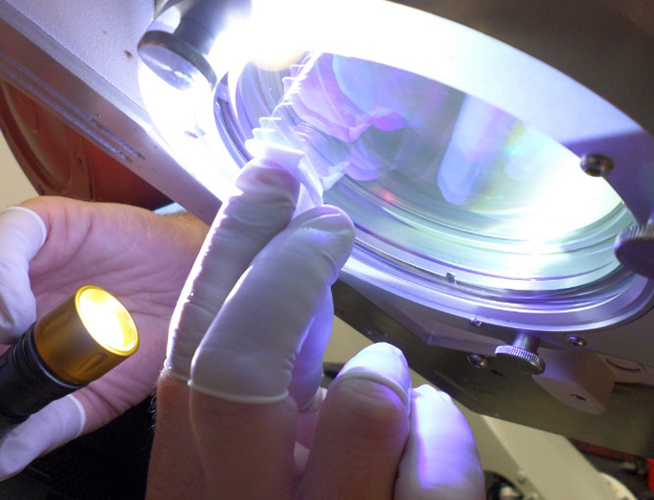

The cover slide is one of the components with central importance for laser welding. It effectively protects the scanner mirrors and focusing optics that are placed behind to guarantee a high beam quality with small power losses. It is important to keep the above cover slide completely free of deposits since its contamination can influence the process negatively and therefore it can result in an abortion of the process. For this purpose, the Crossjet is placed underneath the cover slide. By applying a strong air flow, it is used during the process to deflect larger weld spatters, which are ejected at high speed from the joint.

The process nozzles are aimed directly at the joint to remove the welding smoke residue by using a moderate air flow. This prevents an interaction of the laser beamwith air carried material particles.

Safe Also Outside the Process

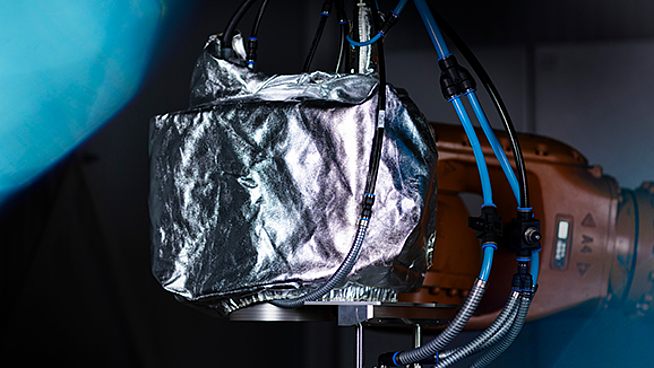

The Fume Protection Module is used to prevent deposits on the cover slide also during the process downtime. Through a permanent air flow, it generates an 'air cushion' directly in front of the cover slide and this prevents the deposit of material particles. Especially cleaned purge air is used for this purpose.