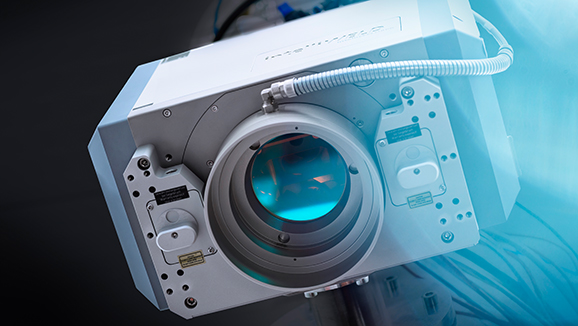

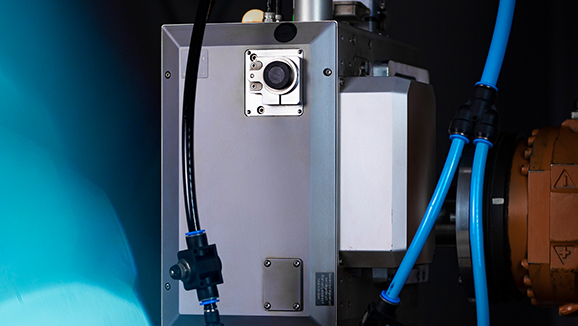

3D scan system

intelliWELD II FT

The Intelligent All-Rounder

- Ideal for lap welds in on-the-fly operations

- Real time status monitoring

- Dimensioned for laser outputs of up to 8 kW

- Optional widening of the focal spot with an optical configuration

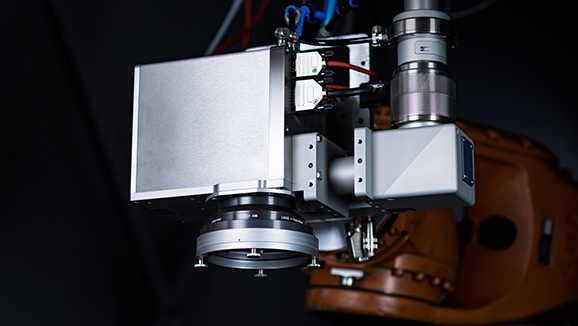

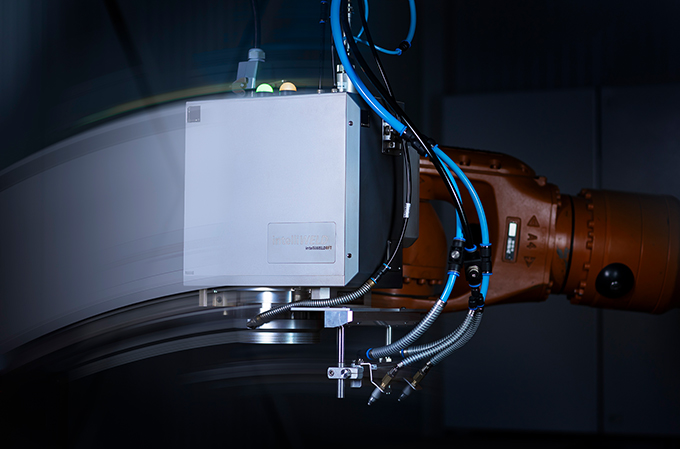

The intelliWELD II FT scan system is designed for the on-the-fly operation for which a handling device moves the scanner over the component to be welded and which executes the welding task at the same time. The fast movements of the deflection mirrors increase the process speed and reduce the positioning time from welding seam to welding seam to a few milliseconds.

A welding figure can optionally be overlain with oscillation geometries to optimize the welding results when facing complex tasks. The intelliWELD II FT can be used flexibly with different spot diameters and seam widths and it therefore is especially qualified for overlap weldings.

Optical Specifications intelliWELD II FT

Options and Expansions

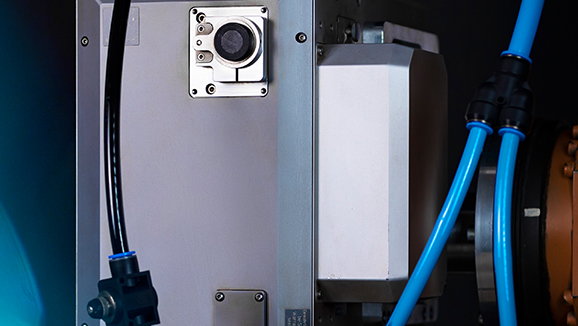

Sensor System Interfaces

- Connection options (C-Mount) for third party sensor systems for process monitoring

- Optionally with and without focus setpoint tracking

Zoom Axis

- Widening of the laser spot up to 150 percent of the actual diameter

- Flexible adaptation of the spot during the process at constant intensity distribution

Cover Slide Sensor

- Early warning system to protect against contamination of the outside cover slide

- Identifies deposits and weld penetrations and issues a warning message

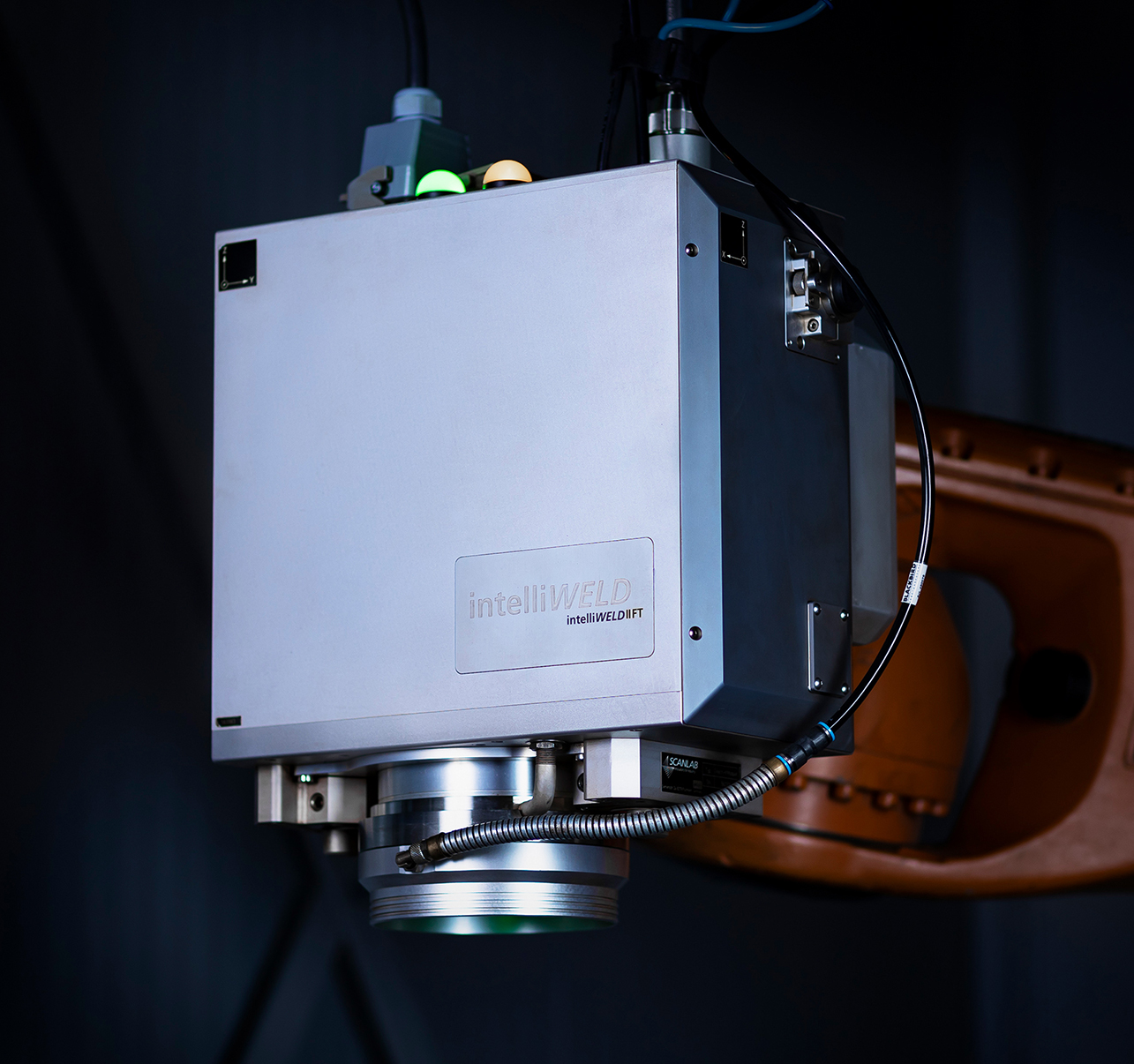

Based on extensions, the intelliWELD II FT can be adapted to the process needs and the ambient conditions. The fully integrated sensor system provides the process-safe setpoint setting of the welding seam for optimal quality. The service life of the system can be increased significantly with the help of industry proven protection and maintenance elements.

Technical Data

| Weight (with / without attachments) | 30.5 kg (w/o zoom), 35.5 kg (w/ zoom) |

|---|---|

| Operating temperature | 25 °C ± 10 °C |

| Supply voltage (supplied by the Blackbird control system) | 30 V DC (29 – 33 V), respective max. 8 A |

| Water cooling specification | 2 l/min at 20 °C and Δp < 0.1 bar; p < 4 bar |

| Filter unit purge air specification | ISO 8573 - 1 : 2010, class 5.4.4 |

| Supplementary set for cooling water connection | Optional |

| Repeatablity (RMS) | < 2 µrad |

| Long term drift over 8 h (at operating temperature) | < 0,15 mrad |

| Tracked camera port observation channel 2 (top) | C-Mount (optional) |

| Double cover slide (beam exit) | Yes |

| Purge Air between inner & outer cover slide | Yes |

| Cover slide sensor (beam exit) | Yes |

| Cover slide collimator | Yes, interchangeable |

| Flow sensor (cooling water) | Yes |

| Teach support | Yes |

| IP protection class | IP54 |

The intelliWELD II FT at a glance

Data sheet intelliWELD II FT