On-the-fly Welding

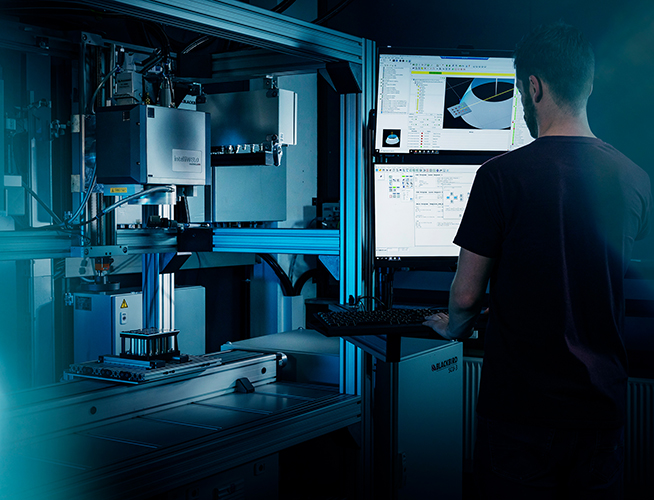

Software

The addition of on-the-fly (OTF) technology to the laser welding process makes it possible to move the scan head and/or the component during welding. The intelligent control system calculates the position of the process points to be welded in advance and continuously adjusts the positioning of the laser beam via galvanometer mirror movements.

- Maximum efficiency and cost-effectiveness

- Precise welding during movement

- Ideal for numerous and/or large workpieces

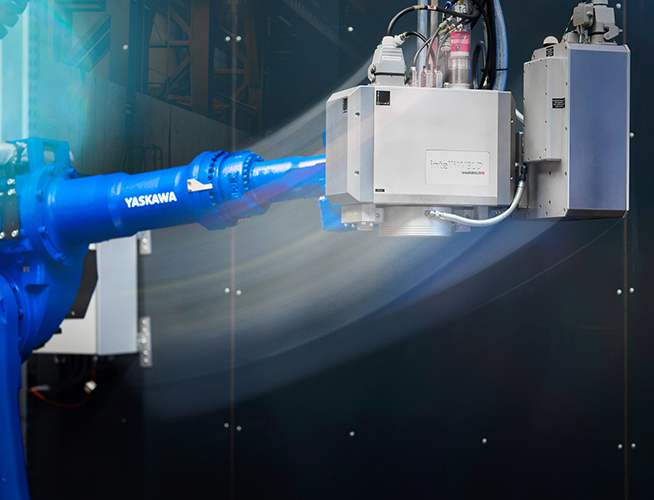

Since 2008, the development of OTF MotionRecord has been setting new standards in on-the-fly laser welding. In remote laser welding (RLW), a robot—typically a 5- or 6-axis system—is used for flexible positioning of the scan head or the component. Precise synchronization between robot movement and scan optics is the key to the actual OTF welding process.

The system really shows its strengths when it comes to complex, three-dimensional components: the robot's high degree of freedom of movement means that even hard-to-reach weld seams can be reliably accessed. This allows even large or geometrically challenging workpieces to be processed efficiently.

Advantages of robot-assisted on-the-fly welding:

- Maximum flexibility thanks to the robot's multiple degrees of freedom

- High accessibility of all welding positions – even with complex 3D components

- Ideal for use in production environments with a wide variety of components

- Production lines can be easily adapted to different component geometries

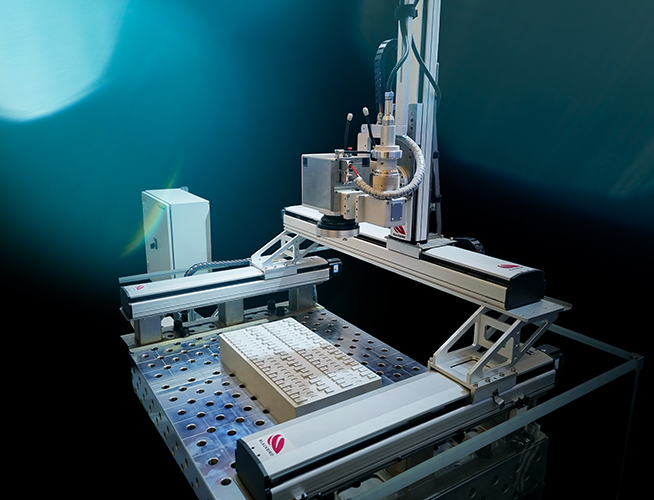

The OTF MotionSync Gantry technology package offers a powerful solution for high-precision on-the-fly remote laser welding. The focus is on robustness and process reliability. As standard, up to two synchronized linear axes can be integrated via encoder signals. This significantly expands the typically limited working range of scan heads – theoretically to component sizes of over 1,000 m². This enables welding applications on very large workpieces (e.g., tailor welded blanks) or on closely spaced individual components such as large battery modules with individual welding points.

Before the automated welding process begins, a so-called record is created in setup mode. This serves as a reference and enables precise comparison with the actual movement of the scan head during execution. Before the process starts, it is ensured that the scan head is in the defined starting position. After the start, the position is continuously monitored in real time (max. sampling rate 4 MHz) – both temporally and spatially – based on the encoder data. Tolerance limits can be defined within which the actual movement must lie. If deviations outside this tolerance occur, the process is automatically stopped. This effectively prevents unwanted degrees of freedom, such as unfavorable beam angles, and ensures consistently high welding quality.

The OTF MotionSync Continuous technology package is the solution for synchronized on-the-fly welding in continuous operation. This software package is specially designed for automated flow production lines and can be used with both a linear axis and a rotary axis. The precise positioning of welds on continuously fed, moving components ensures maximum throughput while maintaining consistent process quality. This is particularly advantageous for high-volume products such as battery packs.

The entire process sequence is started by an external hardware trigger, such as a light barrier. Immediately after the trigger, the encoder value is set to zero, so that a separate position check is not necessary at the start. The motion data is monitored in real time (maximum sampling rate: 4 MHz) based on defined tolerance ranges (temporal or spatial). A clearly defined process range for the welding process is stored within the program. The process is automatically reset and restarted when the next trigger arrives, making it ideal for continuous, short-cycle applications with high throughput. Once welding is complete, the next component can be processed immediately.

OTF at a Glance

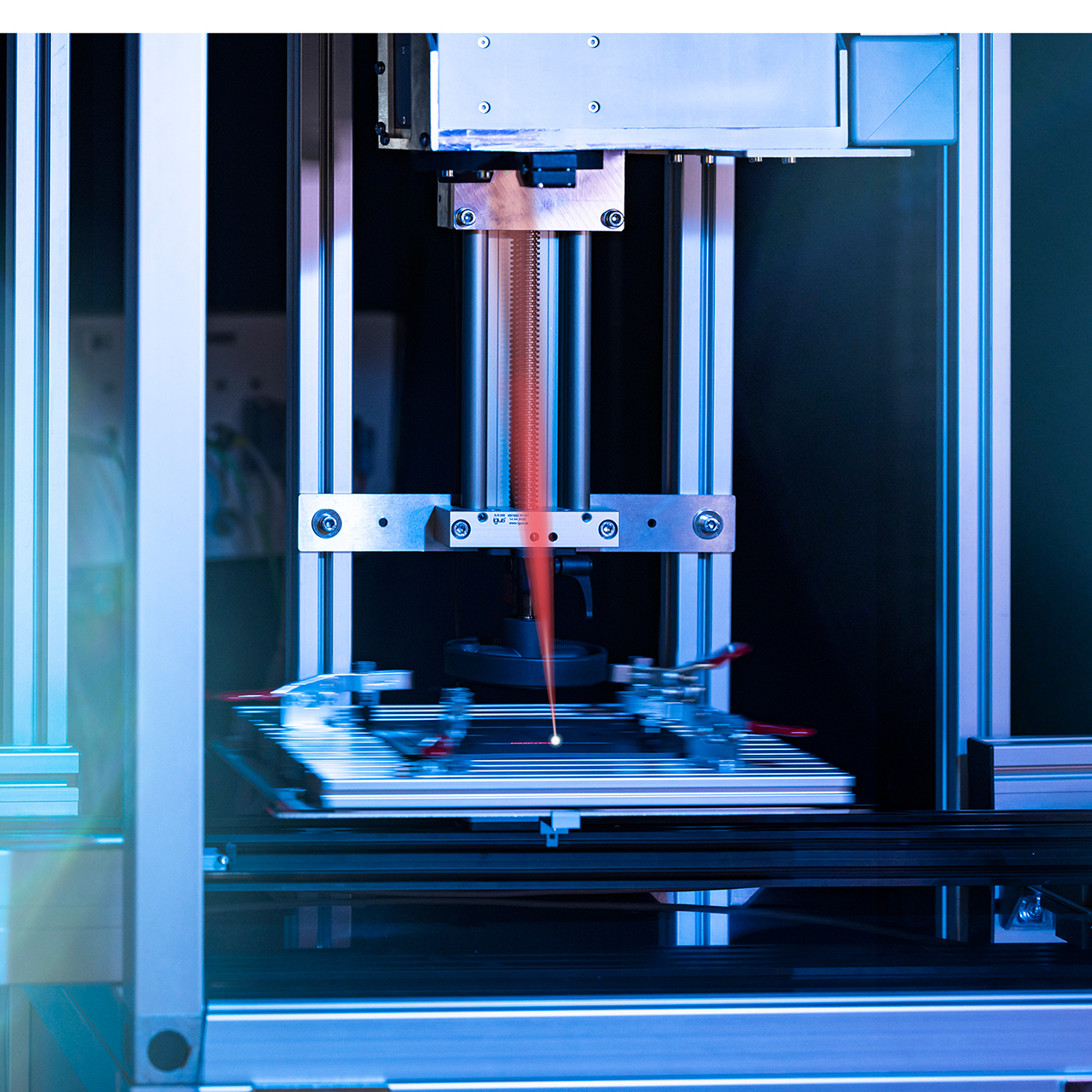

Intelligent Motion Control Directly in the Controller

SCU and SCB optimize your processes

Blackbird's powerful ScanControlUnit (SCU) and ScannerControlBox (SCB) scanner controllers synchronize the movements between the scan head and the handling device, ensuring maximum process efficiency. Various key parameters, such as the beam angle during the planned welding process, can be calculated and adjusted to the desired tolerances. The results are high efficiency, shorter process times, and increased productivity in manufacturing processes.

Further information on the individual control types can be found on the respective product pages.