Seam Inspection with OCT

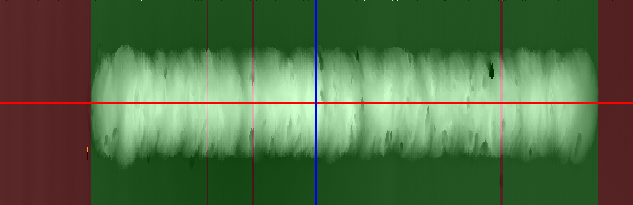

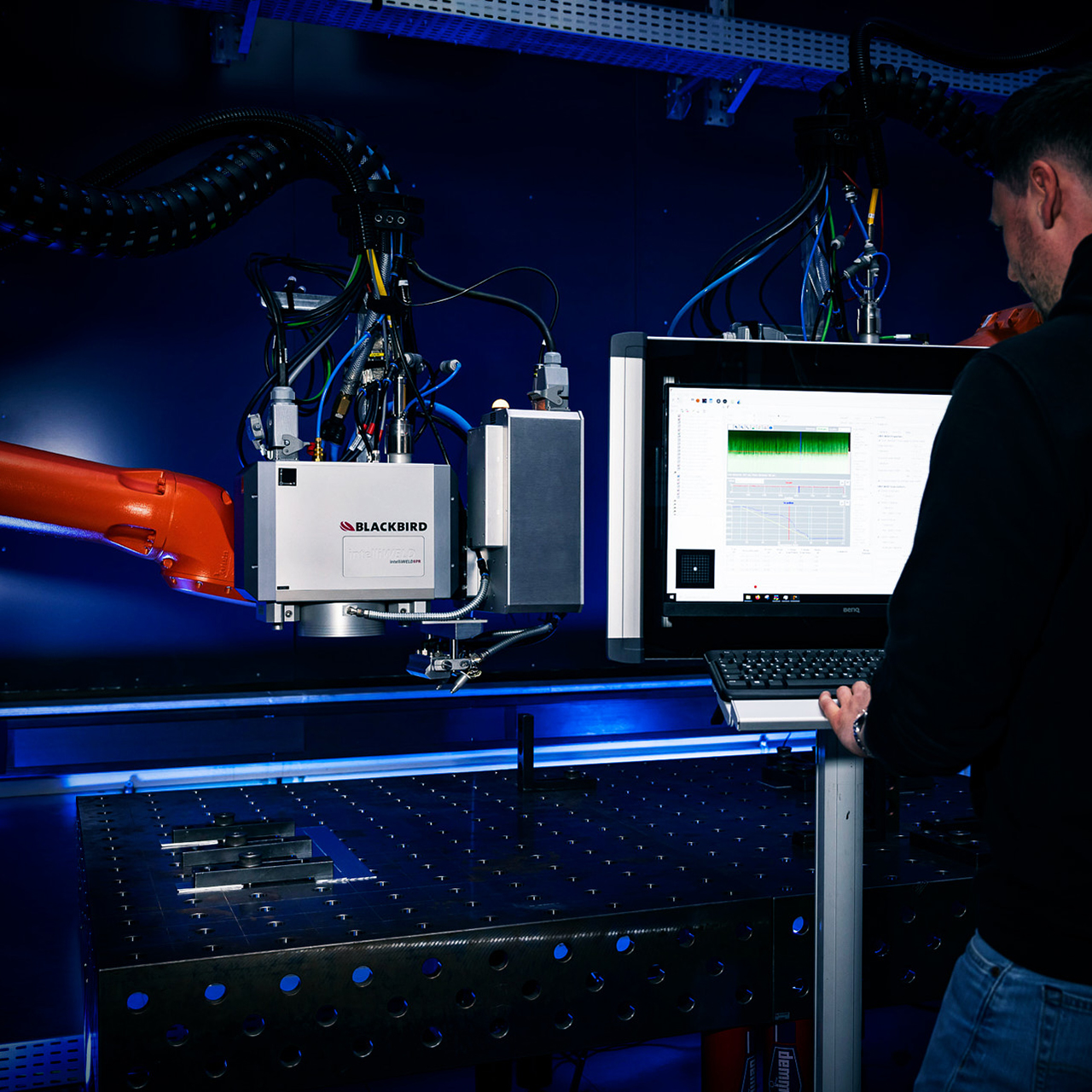

Optical coherence tomography (OCT) has established itself as a key technology in weld seam quality assurance. Through non-contact, high-resolution 3D measurement directly in the manufacturing process, OCT enables fully automatic and objective inspection of seam geometries and surface features. Compared to conventional camera systems, OCT provides more detailed information about the seam structure – ideal for the requirements of modern laser welding processes.

Your advantages at a glance:

- Real-time inspection of every seam – directly during welding

- Early detection of critical defects – avoids rework and scrap

- Precise measurement data with micrometer resolution

- Complete documentation for traceability and process optimization

How the OCT Seam Inspection Process Works

Our solution is based on a multi-stage analysis model that enables precise and flexible evaluation of weld seam quality:

1. Definition phase – Determination of test parameters

In this phase, individual tolerance limits are defined for each relevant seam defect. These define when a feature is considered defective and how many defective areas are permissible within a seam. The detection of recurring, cumulative defects – such as pores or holes – is also parameterized here.

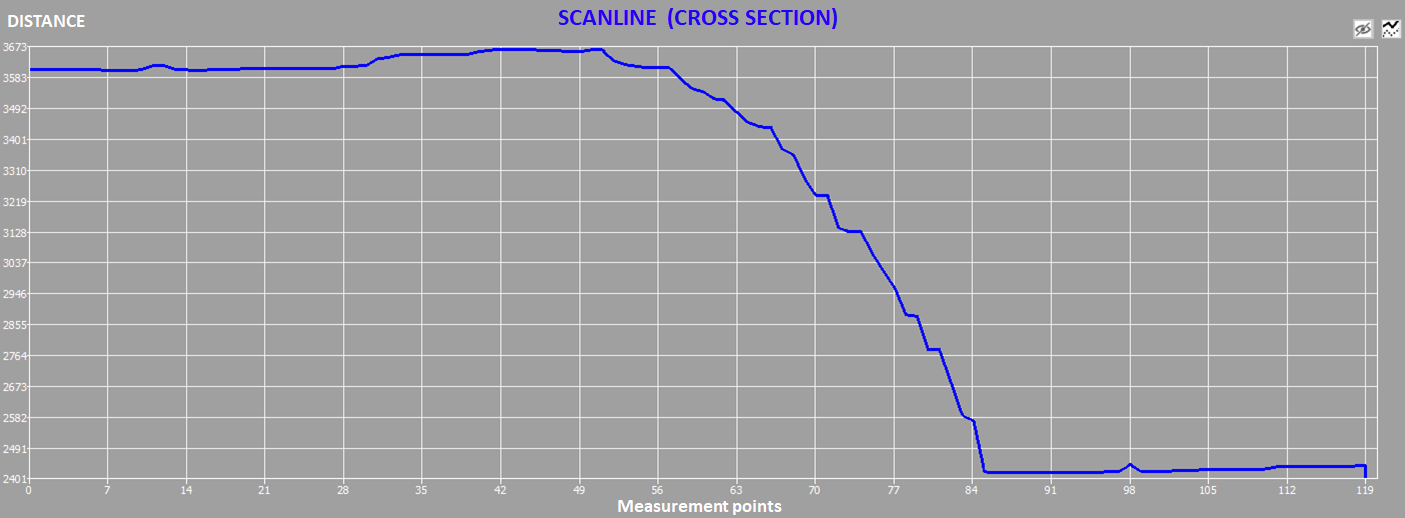

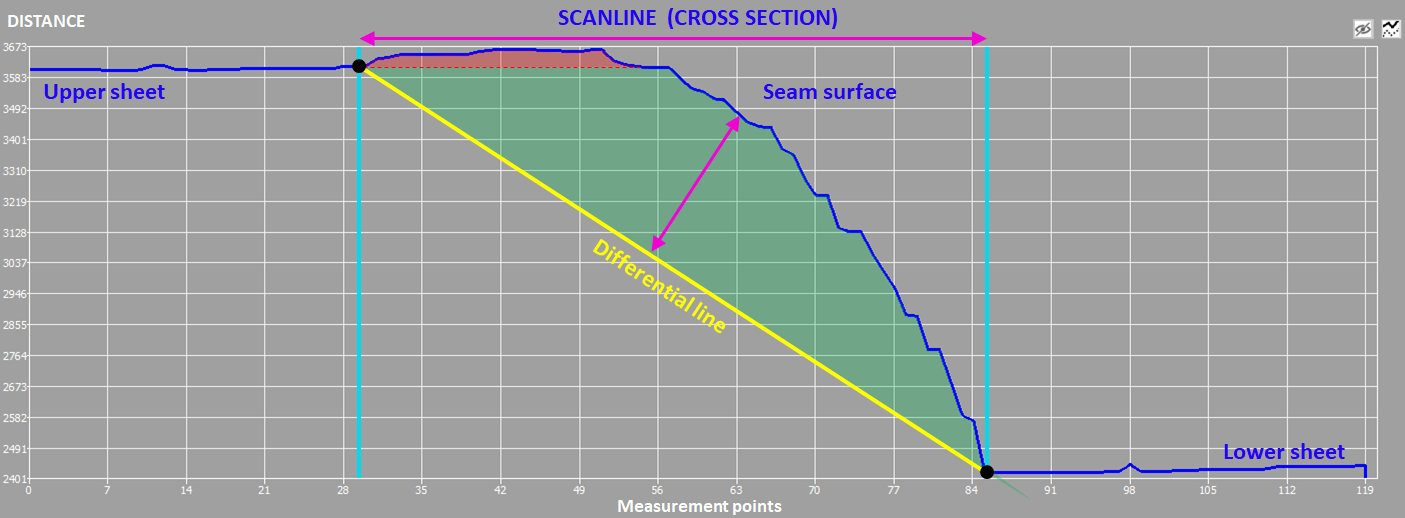

2. Evaluation phase – Automatic analysis of each measurement line

During the process, each individual measurement line is checked for exceeding the previously defined limit values. Defective lines are counted, and patterns of repeated individual deviations can be recognized as collective defects.

3. Final evaluation – Overall evaluation of the seam

At the end of the process, the percentage of defective lines is determined. This results in a score value that summarizes the quality status of the seam. In addition, particularly noticeable defects are documented.

Our algorithms for defect classification and seam evaluation are continuously being reviewed and expanded to cover new requirements, materials, and welding processes. For information on currently available defect coverage or for individual testing requirements, don't hesitate to get in touch with our sales team.

Flexible data Transfer – Seam Inspection Perfectly Integrated into the Process

The quality data obtained can be seamlessly integrated into your production control system – both in real time and downstream:

During the process (inline):

- OK/NOK bit on the fieldbus for immediate feedback

- Cause signal (error type) in case of NOK for targeted response in the process

After the process (offline or documentary):

- Transfer of all measurement data and evaluations via open interfaces such as OPC UA

- Ideal for traceability, analytics, and long-term documentation