Numerous industrial applications require application-specific laser welding components and scalable system configurations. Furthermore, mass production, such as battery manufacturing, requires the highest cycle times while maintaining demanding quality standards. Blackbird's new parameterizable Vision-on-the-fly interface is used to fine-tune welding parameters during ongoing processing, even in a continuous shift. The new solution not only guarantees control and monitoring of all machine and welding parameters, but is also open to the integration of camera-, photodiode-, or OCT-based quality control. Users gain additional flexibility for cost-effective production in the best possible quality.

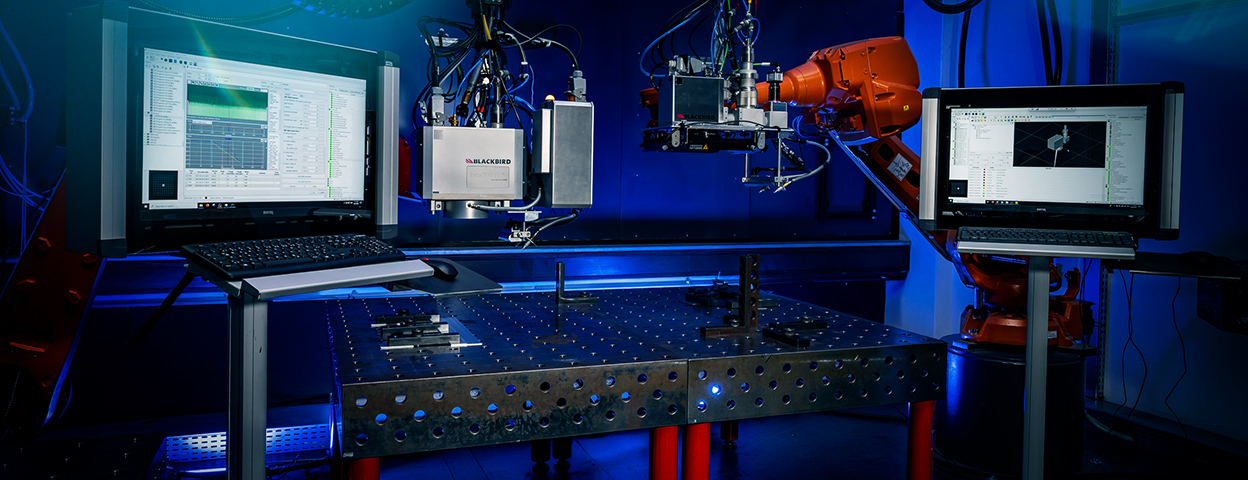

Functionality has been successfully tested and confirmed in a pilot project with thyssenkrupp Automation Engineering in the 'High-Speed Laser' (HSL) machine system. The machine design used in the pilot project enables smooth processing of any sized workpieces in vertical or horizontal joining directions.

The suitable OCT for every laser welding task

Thanks to the intensive collaboration with its sister company Lessmüller Lasertechnik GmbH, Blackbird is presenting a new generation of its OCT solution package this year, with two different application variants. The combination of an intelliSCAN FT scanner with xKITE OCT system offers a compact solution for mobile 2D applications, perfectly suited to the requirements of electromobility and battery production.

The proven combination of a 3D scanner with the xHAWK OCT solution offers maximum dynamics and can be used flexibly with single- and multi-mode lasers. Both solution packages have a 250 kHz measurement rate, can be controlled via ScanControlUnit (SCU) or ScannerControlBox (SCB) scanner controllers, and easily parameterized using Blackbird's user-friendly RSU application software.

When developing the systems, Blackbird paid special attention to their robustness for use in harsh production environments. These solutions convince every day with their performance and smooth hardware interaction with the new software version.