Scanner Controller

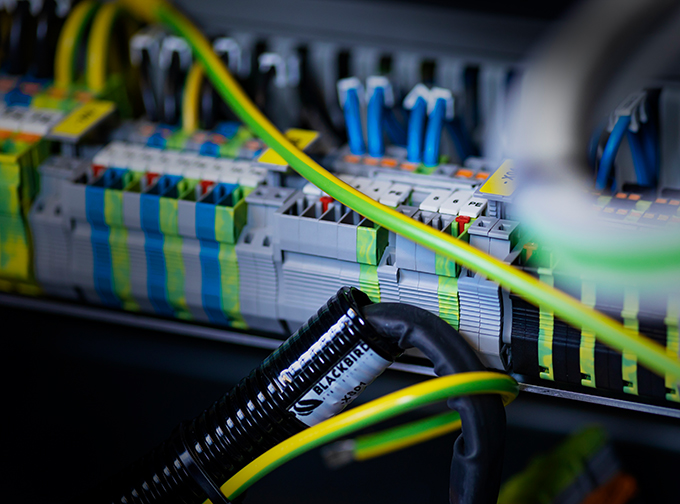

ScanControlUnit (SCU)

The Variable Controller Solution

- Flexible controller for all Blackbird scanners

- Easy exchanging and supplementing of modules

- Can be extended by an OCT measuring system

- All software options from 2D-Basic to 3D on-the-fly

The ScanControlUnit (SCU) is the “all-rounder” among the Blackbird controllers and - based on its flexibility - it can be used without restrictions for all applications. All processes can be covered by the control unit, from small parts productions with high-precision positioning up to meter-long lap weld seams on large BIW automotive parts with simultaneous laser measurement of the process zones.

The SCU is compatible with all Blackbird software packages (2D-Basic, 3D-Basic, 3D-Positioning, 2D-OTF and 3D-OTF). The modular design also permits the extension of the control unit by all Blackbird supplemental slide-in modules. This includes the add-ons for the Blackbird ScaVis camera solution, the RTX function for the positioning of linear axes and the OCT measuring system. The high-performance processor of the SCU permits fast data processing and program adaptation for an efficient system performance - also when using several extensions.

Technical Data

| Weight | approx. 200 kg |

|---|---|

| Height | variable from 880 – 1880 mm |

| Width | 660 mm |

| Depth | 800 mm |

| Power Supply | 100 – 240 V, incl. UPS |

| IP Protection Class | 54 |

| Languages | DE / EN |

| Scanner Control | X, Y and Z axis movement XY2/100, 16-bit resolution SL2/100, 20-bit resolution |

| Robots | Integration packages incl. on-the-fly connection available for: ABB, FANUC, KUKA, YASKAWA MOTOMAN, COMAU, KAWASAKI |

| Fieldbus | DeviceNet, PROFIBUS, PROFINET RT, EthernetIP |

| Safety Interface | Hardwiring, PROFIsafe (based on PROFINET RT), DeviceNet Safety |

All connections are placed easily accessible at the front of the control unit. A simple and fast integration into your system is therefore guaranteed.

Based on the modular design, individual slide-in modules can be easily replaced in case of damages. This guarantees a smooth operation of your system.

The SCU at a glance

Data sheet ScanControlUnit SCU-3